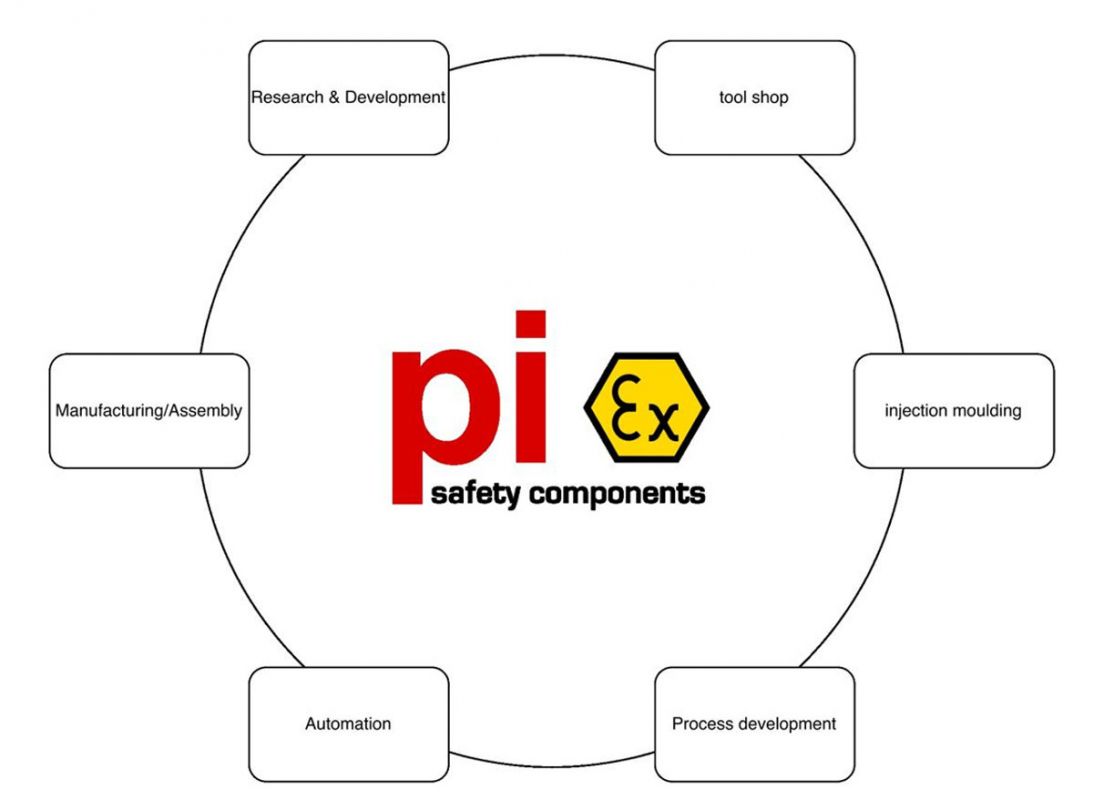

Pi safety works in these areas of expertise

At pi safety, we have numerous areas of technical expertise at our disposal – from research and development to process development, injection moulding, manufacturing/assembly to automation and tool shop – all from a single source.

This comprehensive structure gives pi safety a decisive advantage: we can accompany, coordinate and optimise every single product phase – with maximum transparency, flexibility and efficiency for our customers.

An overview of our areas of expertis

- Research and development

Our research and development department is at the heart of pi safety and has more than 20 years of experience in the fields of explosion protection, actuators and sensor technology. This enables us to guarantee the highest level of technical precision and the continuous development of our product lines. Our engineers work daily to develop innovative technologies that combine safety, efficiency and sustainability. Modern testing procedures and development processes ensure that our products function reliably even under extreme conditions. For pi safety, research and development means not only innovation, but also responsibility – towards people, the environment and industry. Our aim is to actively shape the future of industrial safety and to advance technological progress a little further every day. - Process development

Using advanced software, we have systems at our disposal that allow us to monitor all operational processes at every stage. This ensures continuous data transparency from design and tool and process development to the finished product. As a result, current statuses can be tracked at any time and throughput times can be optimised in a targeted manner. - Injection moulding

With modern moulding machines and clearly structured processes, we have manufacturing capacities of the highest quality at our disposal. This enables us to achieve economic value creation through the intelligent interaction of people and technology. - Automation

We can draw on our own development resources in the field of process automation. This allows labour-intensive activities to be organised efficiently. By integrating innovative solutions into existing processes, production in Germany remains globally competitive. - Manufacturing/Assembly

The close connection between development, design and automation ensures optimal throughput times, high process reliability and consistently high quality – at a competitive price-performance ratio. - Tool shop

pi safety has a partially and fully automated, air-conditioned toolmaking facility that enables the production of precise and economical injection moulding tools. Thanks to state-of-the-art technology and comprehensive development expertise, we can support the entire process – from design to the final product.

The pi safety advantage

With all these areas of expertise at our disposal, we can provide targeted support and efficient implementation at every step – from the initial idea to the finished product. This enables short communication channels, clear communication and a high degree of flexibility. The result at pi safety is innovative solutions, efficient processes and reliable results – all from a single source.

EASY – SAFE – SMART

Fast availability and fast delivery times worldwide!

Contact us for more information: