ATEX-certified products from pi safety

for potentially explosive atmospheres

-

Easy parameterization on the device – no software tool required

-

Extremely durable – thanks to robust IP66 housing

-

Fast, ready-to-connect “plug & play” solution

pi safety: Your specialist for explosion protection products "made in Germany"

Potentially explosive atmospheres require maximum safety and certified technology. pi safety specializes in Ex-certified products for industry, including actuators, volume flow controllers, sensors, pressure transducers, and switching amplifiers. Our devices are specially designed for use in Ex zones 1, 2, 21, and 22 and comply with international standards such as ATEX, IECEx, UKEx, and EAC.

Whether in gas or dust atmospheres, for example, with IP66 protection, temperature resistance from –40°C to +70°C, and robust construction, our components offer reliable operation in the most demanding environments.

Thanks to their compact design, universal interfaces (4–20 mA, 0–10 V) and plug-and-play installation, our Ex products can be quickly and safely integrated into existing systems – perfect for chemical plants, power stations, offshore platforms, or dusty-laden industrial buildings. Our EASY-SAFE-SMART concept guarantees easy installation, maximum safety, and intelligent functionality. Discover our reliable products for your demanding process and building automation tasks.

Discover our reliable products for your demanding process and building automation tasks.

Innovative pi safety Products for ATEX Applications with the EASY-SAFE-SMART Concept

We offer our customers innovative electric actuators, transmitters and sensors for ATEX applications in potentially explosive atmospheres. Our EASY-SAFE-SMART concept guarantees simple installation, maximum safety and intelligent functionality.

Discover our reliable products for your demanding process and building automation tasks.

Actuators with Hazardous area Ex approval for applications in potentially explosive areas Electric, compact, optionally with safety position (QT.Ex series)

QT.Ex-M, Electric Actuators,

explosion protected

- ATEX / IECEx / UKEx / KC / INMETRO / EAC certified

- Integrated terminal box

- Ambient temperature -40…+70 °C

- Optional control / feedback 0…10 V; 4…20 mA

- IP66

- For use in Zone 1, 2, 21, 22

- Stainless steel / polymer compound material for highest

- Corrosion resistance

- Optional safety setting / spring return

Technical data

| Specification | II2(1)G Ex db eb ib mb [ia Ga] IIC T4 Gb II2(1)D Ex tb [ia Da] IIIC T130°C Db II2 G Ex h IIC T4 Gb II2 D Ex h IIIC T130 °C Db |

| Manufacturer | pi safety components |

| Auxiliary Switch | 5° / 80° switching points max 250 V / 0.1 A min. 5 V / 5 mA |

| Rotation Angle | 95° (5° pre-tension) |

| Axis Mount | 12 x 12 mm (double square) |

| Power Consumption | 5 W / 7 VA Holding position 20 W / 30 VA Motor 30 VA / 2 A Dimensioning |

| Humidity Range | 0...95% r.H. without condensation |

| Temperature Range | -40...+70°C |

| Housing Material | High-tech polymer Halogen- and silicone-free |

| Housing Protection | IP66 |

| Dimensions | Approx. 320 x 120 x 85 mm |

Transmitters & sensors for Ex zones With 4–20 mA or 0–10 V output, for temperature, pressure, humidity (TR.Ex & IY.Ex)

TR.Ex Transducer,

explosion protected

Specifications:

- II2(1)G Ex eb mb ib [ia Ga] IIC T4 Gb

II2(1)D Ex tb ib [ia Da] IIIC T130°C Db - Universal transmitter for installation in Zone 1 / 2 / 21 / 22

- Ambient temperature -40…+70°C

- IP66

- Temperature class T4 for all gases and dusts

- Locally configurable; Display

- Stainless steel / polymer compound material

- For highest corrosion resistance

- Feedback: 0...10 V or 4...20 mA

- No additional barrier required in control cabinet

- LED status indicator

- Easy installation

- 24 VAC / DC

- For IY.Ex sensors

IY.Ex Sensors

Specifications:

- II 1/2G Ex ia IIC T6/T5/T4 Ga/Gb

II 2D Ex ia IIIC T75°C-T145°C Db - Intelligent sensor concept for connection

(M12 connector) to TR.Ex universal Ex-transducer - Stainless steel / polymer compound material

for maximum corrosion resistance - Fast sampling rate up to 125 ms

for pressure sensors - Room sensor for dircect connection

- For measuring in zone 0, 1, 2, 21, 22

- Other sensors with M12 sensor cable

(1 Meter included, other lengths available) - For use with Tr.Ex Transducer

Switching amplifiers with relay output for applications in potentially explosive areas For safe signal processing in Ex areas (SW.Ex & IR.Ex.)

SW.Ex Switching Relais,

explosion protected

Specifications:

- II2(1)G Ex eb mb ib [ia Ga] IIC T4 Gb

II2(1)D Ex tb ib [ia Da] IIIC T130°C Db - Universal Ex switch amplifier for installation in Zone 1 / 2 / 21 / 22

- Two configurable switching points / relay outputs

- Ambient temperature -40…+70 °C

- IP66

- Temperature class T4 for all gases and dusts

- Adjustable hysteresis

- Locally configurable, display

- Stainless steel / polymer compound material for highest corrosion resistance

- No additional barrier required in control cabinet

- LED status indicator

- Easy installation

- 24 VAC / DC

- For IR.Ex sensors

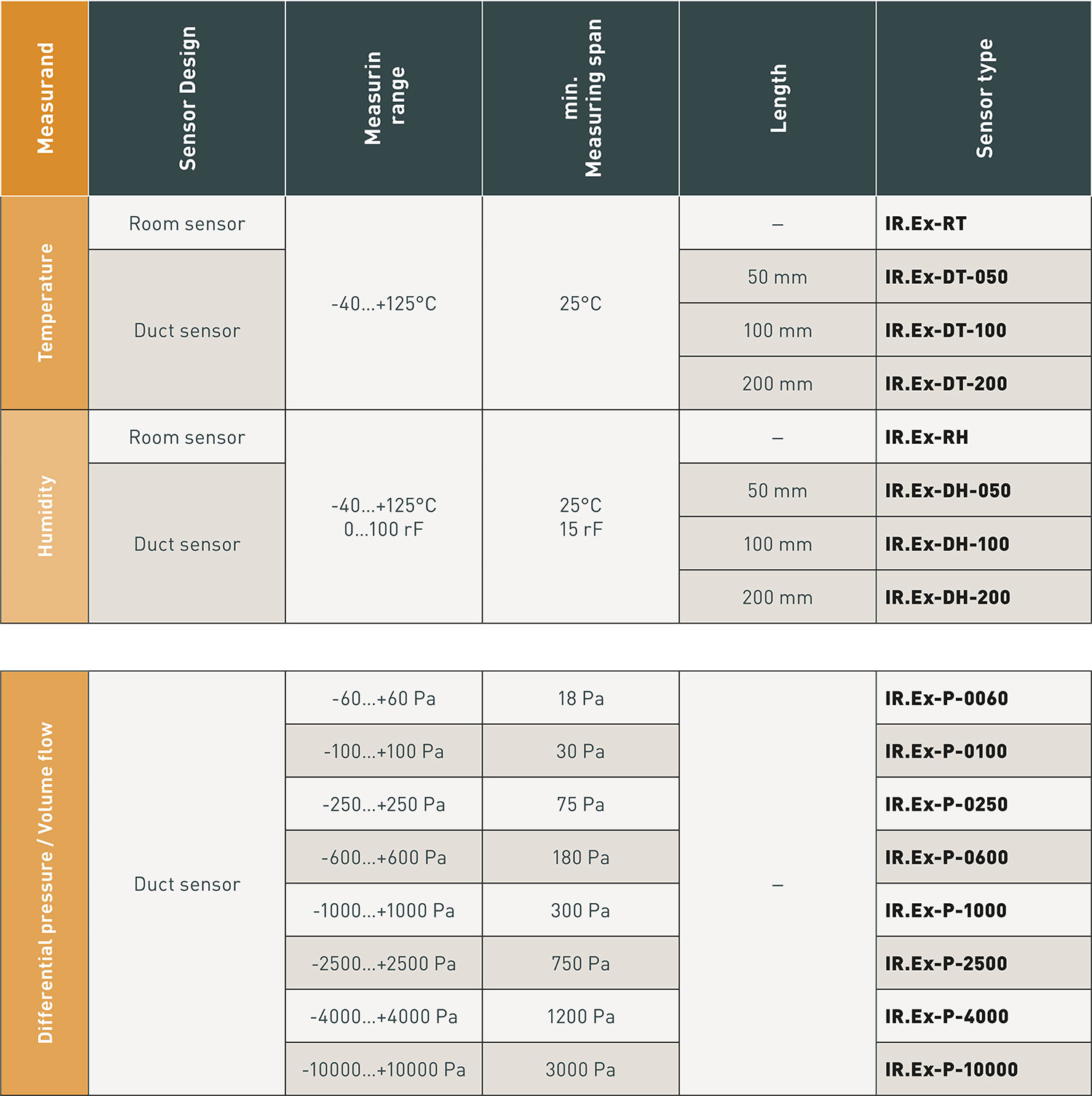

IR.Ex Sensors

Specifications:

- II 1/2G Ex ia IIC T6/T5/T4 Ga/Gb

II 2D Ex ia IIIC T75°C-T145°C Db - Intelligent sensor concept for connection

(M12 connector) to SW.Ex universal Ex-transducer - Stainless steel / polymer compound material

for maximum corrosion resistance - Room sensor for dircect connection

- For measuring in zone 0, 1, 2, 21, 22

- Other sensors with M12 sensor cable

(1 Meter included, other lengths available) - For use with SW.Ex Transducer

AC.Ex volume flow controllers for applications in potentially explosive atmospheres Precise air/gas control, locally adjustable with display

AC.Ex, Volume Flow Controller,

explosion protected

Specifications:

- II2(1)G Ex eb mb ib [ia Ga] IIC T4 Gb

II2(1)D Ex tb ib [ia Da] IIIC T130°C Db - in zone 1 / 2 / 21 / 22

- Ambient temperature -40…+58°C

- IP66

- Temperature class T4 for all gases and dusts

- Adjustable on site

- Integrated, lighted display for measured value indication

- Stainless steel / polymer compound material

for maximum corrosion resistance

QT.Ex and IY.Ex

Specification:

- Feedback: 0...10 V oder 4...20 mA

- No further barrier required in the control cabinet

- LED status indication

- 24 VAC / DC

- For use with IY.Ex-Sensors

- Setpoint specification: 0...10 V oder 4...20 mA

- Low power consumption < 3 W

- Measured value recording in zone 0

- Cable length from transmitter to sensor up to 100 m

- Integrated Ex e terminal box

- Alarm contact potential-loaded

6 advantages of pi safety Ex products

Ex-compliant actuators, sensors and controllers

ATEX, IECEx and UKEx certified components for gas and dust atmospheres in Zones 1, 2, 21 and 22 – designed for safe control, measurement and regulation in hazardous areas

Explosion-proof transmitters and switching amplifiers with IP66

Rugged housing design provides reliable protection against dust, moisture and water jets – ideal for use in harsh industrial environments and outdoor applications with high safety requirements

Quick commissioning thanks to preconfigured interfaces

Simply connect and start – analog outputs (4–20 mA / 0–10 V), relay contacts or M12 connectors preconfigured for common automation environments such as PLC, BMS and DCS systems

Made in Germany: development and production in Bavaria

High manufacturing depth, tested quality and short communication paths – complete development, production and final inspection at the German site

Reliable support, short delivery times, OEM options on request

Technical support without call center queues, direct project contacts – customized solutions for OEM partners and flexible delivery schedules for assemblies or series production

Ideal for process industry, power plants, offshore, HVAC and mechanical engineering

Consistent suitability for demanding industries with explosive atmospheres – from chemical and energy technology to maritime applications and air handling or conveyor systems

Our Ex-certified industrial products enable safe automation in hazardous environments – with minimal integration effort.

Industries and typical areas of application for ATEX products from pi safety

Chemical and petrochemical industry

Chemical and petrochemical industry

Oil & gas / offshore platforms

Mills, silos, recycling, cement plants

Energy generation / biogas & power plant technology

Food processing (dust ATEX)

Industrial plants with hazardous substances

Our pi safety products are approved for these Ex zones

- • Zone 1 (gas Ex)– e.g. in chemical plants, paint shops, oil & gas production

- Zone 2 – for occasionally occurring explosive atmospheres

- Zone 21 (dust-Ex) – e.g. in mills, silo plants, powder coating

- Zone 22 – e.g. in food, recycling, or wood processing

Our Ex components meet all requirements of Directive 2014/34/EU (ATEX) and offer maximum planning reliability for plant manufacturers and OEMs.

FAQ about ATEX-certfified products from pi safety

-

ATEX stands for the French term Atmosphères Explosibles and aims to protect people, the environment and machinery from explosion hazards. The ATEX directives apply to all devices, machines and protective systems that are used in areas with a potential explosion hazard.

-

The main difference between ATEX and IECEx is that ATEX certification is only valid in the countries of the European Union, whereas IECEx certification is recognised internationally.

IECEx is an international certification system for equipment used in potentially explosive atmospheres. It stands for

“International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres.”

The aim of IECEx is to facilitate international trade in Ex-certified equipment by harmonizing globally applicable safety standards – comparable to the European ATEX directive.

The IECEx certificate confirms that a product has passed certain tests in accordance with international standards and that a recognized quality assurance system (QAR) is in place. Essential standards for electrical equipment are:

- IEC 80079-0 – General requirements

- IEC 80079-18 – Equipment with functional safety

- IEC 80079-31 – Dust explosion protection

Manufacturers such as pi safety receive a Certificate of Conformity (CoC) after successful testing. In addition, so-called ExTRs (Explosion Protection Test Reports) can be used as a basis for national approvals.

Advantage for B2B customers: IECEx products such as those from pi safety enable simplified market access worldwide and ensure a uniform, high level of safety.

An actuator is a mechanical or electromechanical device that is used to execute movements or hold certain positions. It converts electrical energy into mechanical movement and is used to control machines or systems.

Typical tasks of an actuator:

- Regulating or controlling processes: For example, opening or closing valves, dampers or slides.

- Electric actuators work with electric motors, are precise and are often used in automated systems.

- Actuators are used in various areas such as the process industry, building technology and automation technology.

Explosion protection is a specialised field of technology that deals with the prevention of explosions. As part of safety engineering, it aims to prevent damage to people and property. Areas of application in which explosion protection is often required are: Oil & gas, renewable energy (H2), medical technology, laboratories & clean rooms, industrial bakeries and shipbuilding.)

The various IP enclosure protection classes describe the protection of objects against dust and water, with the first digit describing the degree of protection against dust and the second digit against water.

Our products are all IP66 certified. The first 6 stands for ‘totally protected against dust ingress’ and the second 6 for ‘high pressure water jets‘.

Our products are made from a plastic composite material developed in-house.

Stainless steel fibres are incorporated into this material. This allows the protective conductor to be connected directly to the housing.

The material also has a number of advantages. All products are not only resistant to salt water and chemicals, but are also lighter and therefore easier to handle compared to other competitors.

A spring return actuator is a special type of actuator in our product range. A mechanical spring is used here, which ensures that the actuator assumes and maintains the desired emergency position in the event of a malfunction or emergency (power failure, fire, etc.). Without any battery packs or similar.

All our products have an integrated connection box to supply and wire the devices electrically. NO additional connection unit is required.

- Actuator series:

Our actuators can be mounted and operated both clockwise and counter-clockwise. The integrated patented connection box can be easily removed using two screws and can be reattached at an angle of 180°. This ensures barrier-free access to the connection box at all times.

EASY - SAFE - SMART - Sensors:

Both our measuring transducer (TR.Ex/Nc) and the switching amplifier (SW.Ex/Nc) are identical in design. The power supply unit can be removed using a simple plug-in connection, mounted separately and reassembled after wiring.

EASY - SAFE – SMART

-

ZONE 0: A hazardous, explosive atmosphere consisting of a mixture of air, flammable substances in the form of gas, vapour or mist is present continuously, for long periods or frequently.

-

ZONE 1: A potentially explosive atmosphere consisting of a mixture with air of flammable substances in the form of gas, vapour or mist is present occasionally during normal operation.

-

ZONE 2: A hazardous, explosive atmosphere consisting of a mixture of air, flammable gases, vapours or mists is not normally present or is present only briefly.

-

ZONE 20: A hazardous, explosive atmosphere in the form of a cloud of combustible dust is present continuously, for long periods or frequently.

-

ZONE 21: A hazardous, explosive atmosphere in the form of a cloud of combustible dust is present occasionally during normal operation.

-

ZONE 22: A hazardous, explosive atmosphere in the form of a cloud of combustible dust is not normally present or is present only briefly.

-

A measuring transducer is a device that converts physical measured variables such as temperature, pressure, flow or humidity into a standardised electrical signal. This signal can then be further processed by control and monitoring systems.

-

The main task of our measuring transducer is signal conversion: converting a measured value (e.g. pressure) into an electrical signal (e.g. 4-20 mA, 0-10 V).

-

A sensor records the physical variable and the transmitter processes the sensor signal, adapts it and converts it into an electrical output signal.

-

Examples of sensors:

Temperature measurement, pressure monitoring, humidity measurement and combinations of these.Transmitters are an indispensable part of industrial automation and process monitoring.

A switching amplifier is an electronic circuit that amplifies signals while simultaneously acting as a switch. This means that it is used in certain applications to switch between two states (on/off), converting a weak control signal into a stronger output signal.

Main functions of a switching amplifier:

- amplification:

The switching amplifier increases the strength of an input signal so that it can be used for further processing or applications. - switching function:

It operates either in the on state (saturation) or in the off state (blocking), similar to a digital switch. This is particularly important in digital electronics applications.